Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

Kaizen at Giorgio Foods

Frederic J. Giorgi, Chairman of Giorgio Foods Inc, shares the tremendous impact that kaizen has had on his organization, not only in the reduction of costs and increase in profitability, but also in employee attitudes.

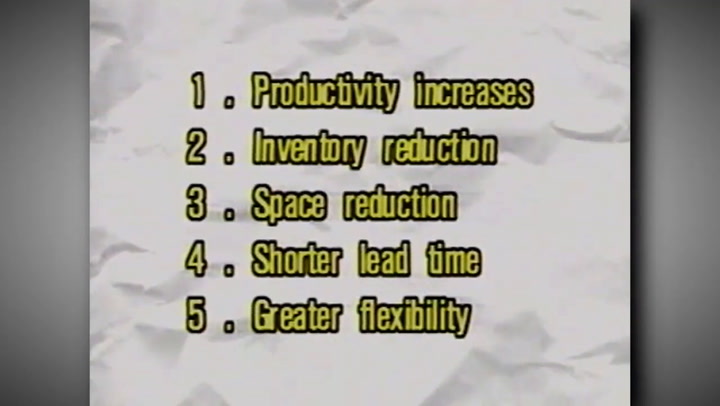

- 0:05 – How JIT reduces production costs

- 0:26 – An additional benefit of JIT: Attitude change

- 0:40 – About Giorgio Foods, Inc

- 1:00 – Kaizen’s effect on Giorgio Foods’ bottom line and employee attitudes

Course Videos

Introduction To JIT Pays

01:34

2Gemba Kaizen JIT Pays

03:43

3One Piece Flow at Wiremold

08:35

45S at Yasda Precision Tools

02:30

Current Video

Kaizen at Giorgio Foods

11:14

Next VideoFlexibility with U-Shaped Cells at Matsushita Electric Works

04:27

7Changing Hearts and Minds with Kaizen

04:12

8Value-Added Work and the 7 Types of Waste

05:29

9The Muda of Overproduction

01:31

10The Muda of Waiting

01:17

11The Muda of Transportation

02:04

12The Muda of Processing

01:13

13The Muda of Inventory

02:48

14The Muda of Motion

01:21

15The Muda of Producing Rejects

02:33

16Converting from a Conveyor Line to a U-Shaped Cell at Yoshitake Inc.

08:03

17Going to the Gemba to See the Waste

03:03

18Push Production vs. Pull Production

03:03

19One Piece Flow And Multi-process Handling

13:57

20Leveling Production

02:14

21Setup Reduction Kaizen

02:38

22Standard Work

04:04

23Part Supply and Kanban

04:49

24JIT Pays: 5s

05:11

25JIT Pays: Visual Management

02:20

26What Does Kaizen Mean to You?

01:12

You must be logged in to access Gemba Academy resources.

Video Resources

Quiz

Course Resources

Quiz

Next Video Flexibility with U‑Shaped Cells at Matsushita Electric Works

Matsushita Electric Works’ Sr. Managing Director, Mr. Yukinobu Nishida, explains how his organization discovered that automation was not the ultimate solution to improve production and profits. Instead, kaizen and JIT proved to be the best choices in addressing new, more demanding lead times as they integrated employees into perfect production systems.