Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

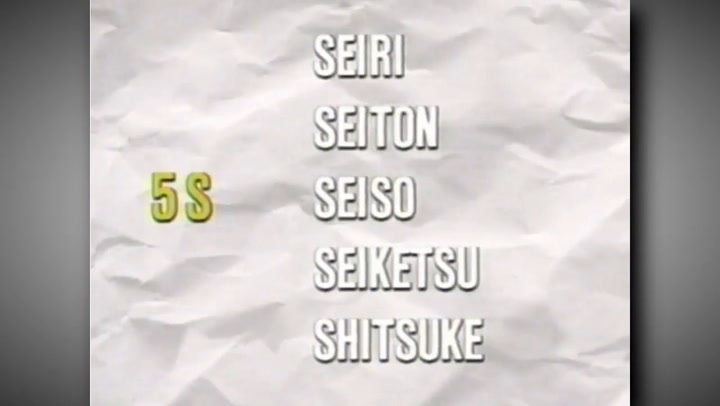

JIT Pays: 5s

Learn what 5S is and why it is such a fundamental part of the lean production system.

- 0:17 – What the 5S’s stand for

- 0:53 – Seiri and red tagging

- 2:50 – Seiton and the proper placement of all things used in the gemba

- 4:13 – Seiso cleaning and upkeep

Course Videos

Introduction To JIT Pays

01:34

2Gemba Kaizen JIT Pays

03:43

3One Piece Flow at Wiremold

08:35

45S at Yasda Precision Tools

02:30

5Kaizen at Giorgio Foods

11:14

6Flexibility with U-Shaped Cells at Matsushita Electric Works

04:27

7Changing Hearts and Minds with Kaizen

04:12

8Value-Added Work and the 7 Types of Waste

05:29

9The Muda of Overproduction

01:31

10The Muda of Waiting

01:17

11The Muda of Transportation

02:04

12The Muda of Processing

01:13

13The Muda of Inventory

02:48

14The Muda of Motion

01:21

15The Muda of Producing Rejects

02:33

16Converting from a Conveyor Line to a U-Shaped Cell at Yoshitake Inc.

08:03

17Going to the Gemba to See the Waste

03:03

18Push Production vs. Pull Production

03:03

19One Piece Flow And Multi-process Handling

13:57

20Leveling Production

02:14

21Setup Reduction Kaizen

02:38

22Standard Work

04:04

23Part Supply and Kanban

04:49

Current Video

JIT Pays: 5s

05:11

Next VideoJIT Pays: Visual Management

02:20

26What Does Kaizen Mean to You?

01:12