Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

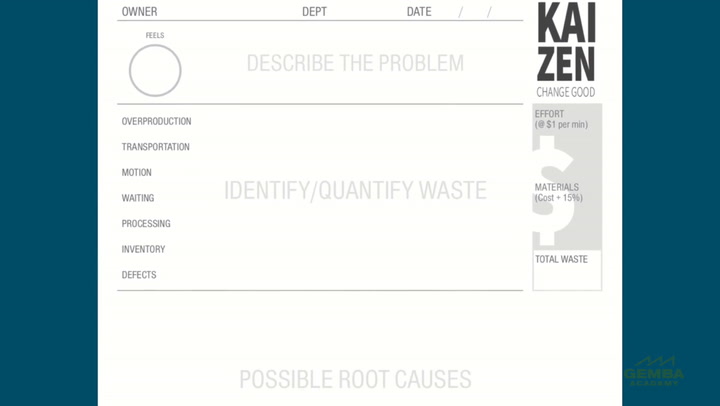

How to Use the Kaas Tailored Kaizen Form

Tucker Kaas, Kaizen Consultant and GM Resident at Kaas Tailored, shares the kaizen form his company uses to eliminate waste.

- 0:19 The problem statement

- 1:12 Identifying wastes

- 2:15 Root cause analysis

- 2:50 Preventive action

Series Videos

A Conversation with Jeff Kaas, President of Kaas Tailored

07:51

2Kaas Tailored Tour Agenda

03:44

3What to Expect on the Kaas Tailored Tour

04:22

4The Gap Between Work and Hobbies

18:02

5How Kaas Tailored Creates High Mix, Low-Volume Flow and Pull

02:59

6Parts Kitting, Limited WIP, and Pull Signals at Kaas Tailored

03:27

7The Ring Toss Visual Pull Signal at Kaas Tailored

04:49

8One Piece Flow Cells at Kaas Tailored

04:51

9How Long-Term Hoshin Objectives Turn Into Annual Goals and Small Experiments

17:21

10The Visual Management System at Kaas Tailored

09:18

11Periodic Review of Results and Improvement of the Hoshin Process

07:25

12The Daily Gemba Walk at Kaas Tailored

06:38

13Visual Management of Status for the Process, the Day, and the Year

03:29

14Daily Accountability Through Team Training at Kaas Tailored

05:08

15Observations About Daily Accountability Processes at Kaas Tailored

08:33

16We Pushed Kaizen for 10 Years, Now We Pull Kaizen

07:53

17A Problem Solving Example in Purchasing at Kaas Tailored

16:31

18A Kaizen Example from Upholstery Process at Kaas Tailored

10:39

19A Kaizen Example from Human Resources at Kaas Tailored

11:11

20How Guiding Principles Engage People to Grow the Business and Themselves

14:31

Current Video

How to Use the Kaas Tailored Kaizen Form

05:53

Next VideoWhat's the Next Challenge for Kaas Tailored?

21:01

You must be logged in to access Gemba Academy resources.

Next Video What’s the Next Challenge for Kaas Tailored?

Jeff Kaas, President of Kaas Tailored, explains the obstacles they’ll focus on in the coming months, how they’ll make the culture of improvement permeate the DNA of the company, and more.