Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

How to Practice Visual Management in a Cell

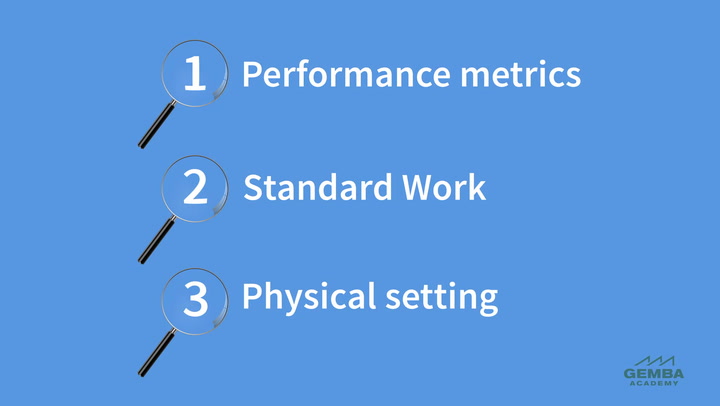

Building a cell brings equipment close together, connects the processes steps, and locates materials and tools within reach. This creates an opportunity to use visual controls to track performance, maintain safety and quality, and respond to abnormalities. Learn the three areas of focus for practicing visual management in a cell.

Course Videos

Managing Cellular Workflow

04:55

2Getting Started with Cell Design

06:36

3How to Perform a P-Q Analysis for Cell Design

05:06

4How to Create a Parts-Process Matrix for Cell Design

07:27

5How Many Cells Do We Need?

07:45

6How to Use a Process Capacity Table for Cell Design

07:16

7When to Build Multiple Slower Cells

07:35

8How to Arrange Equipment in a Cell

07:21

9How to Select Equipment for a Cell

04:41

10What Is Right-Sized Equipment?

05:07

11How to Build Flexibility Into Cells

08:11

12How to Set Equipment Spacing in a Cell

07:26

13How to Design Cellular Workflow Around People

08:26

14What Is a Yamazumi Chart?

04:05

15How to Use a Yamazumi Chart

05:36

16How to Calculate Crew Size for Standard Work

04:05

17How to Move Materials In and Out of Cells

05:03

Current Video

How to Practice Visual Management in a Cell

06:33

Next VideoHow Cells Change Cost Reporting

09:33

You must be logged in to access Gemba Academy resources.