Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

How to Create a Parts-Process Matrix for Cell Design

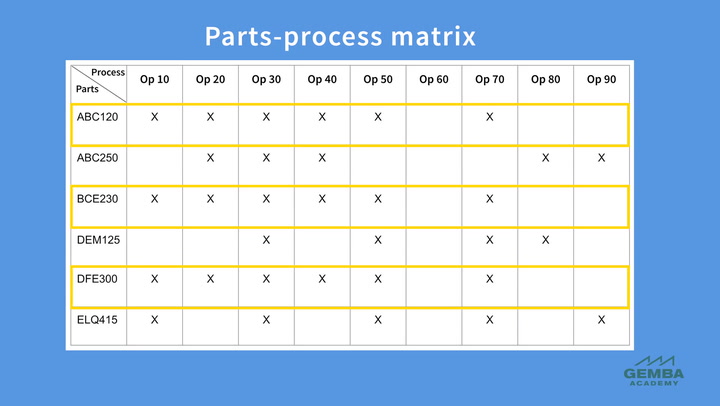

Selecting the items to produce in a cell involves identifying the products with enough demand to justify dedicating equipment, and following a similar process sequence. The parts-process matrix is a visual tool for grouping similar process flows across different products. Learn the steps for using the parts-process matrix to identify product families for a cell.

Course Videos

Managing Cellular Workflow

04:55

2Getting Started with Cell Design

06:36

3How to Perform a P-Q Analysis for Cell Design

05:06

Current Video

How to Create a Parts-Process Matrix for Cell Design

07:27

Next VideoHow Many Cells Do We Need?

07:45

6How to Use a Process Capacity Table for Cell Design

07:16

7When to Build Multiple Slower Cells

07:35

8How to Arrange Equipment in a Cell

07:21

9How to Select Equipment for a Cell

04:41

10What Is Right-Sized Equipment?

05:07

11How to Build Flexibility Into Cells

08:11

12How to Set Equipment Spacing in a Cell

07:26

13How to Design Cellular Workflow Around People

08:26

14What Is a Yamazumi Chart?

04:05

15How to Use a Yamazumi Chart

05:36

16How to Calculate Crew Size for Standard Work

04:05

17How to Move Materials In and Out of Cells

05:03

18How to Practice Visual Management in a Cell

06:33

19How Cells Change Cost Reporting

09:33

You must be logged in to access Gemba Academy resources.