Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

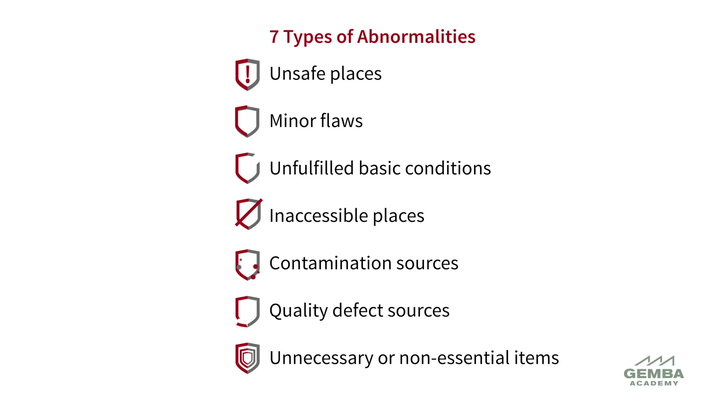

The Seven Types of Equipment Abnormality

A key role of operators in Autonomous Maintenance is to quickly recognize and identify when equipment is operating under abnormal conditions. This prevents accidents, defects, breakdowns and helps to maintain the improvements from TPM. Learn the seven categories of equipment abnormalities and how to incorporate their detection into Autonomous Maintenance activity.

Course Videos

What Is Autonomous Maintenance?

05:09

2Getting Started with Autonomous Maintenance

06:21

3What Is Forced Deterioration?

03:08

Current Video

The Seven Types of Equipment Abnormality

05:03

Next VideoWhat Is Initial Cleaning?

03:51

6Getting Started with Initial Cleaning

05:31

7Safety Precautions for Initial Cleaning

03:22

8How to Perform Initial Cleaning

05:29

9Address Contamination Sources and Hard-to-Access Places

04:39

10Develop Provisional Standards

05:09

11What Is General Inspection?

03:22

12How to Conduct General Inspection

06:01

13Autonomous Inspection

04:19

14Revise Autonomous Maintenance Standards

03:21

15Autonomous Management

06:52

16What Is a One-Point Lesson?

03:59

17How to Create One-Point Lessons

06:23

18How to Use TPM Tags

04:09

You must be logged in to access Gemba Academy resources.