Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

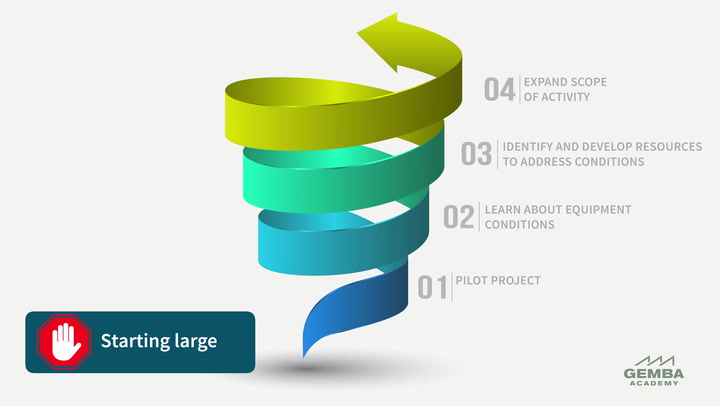

TPM Pitfalls to Avoid When Getting Started

TPM can be implemented in more than one way based on an organization’s needs. However, there are some common pitfalls that all organizations should be aware of and avoid. Learn about each of these common pitfalls and how to avoid them.

Course Videos

TPM Overview

00:05:58

2The 8 TPM Pillars

00:05:02

3The Types Of Maintenance

00:03:57

4Getting Started with TPM

00:03:53

Current Video

TPM Pitfalls to Avoid When Getting Started

00:04:21

Next VideoThe 12 Steps to Implementing TPM, Phase 1

00:06:02

7The 12 Steps to Implementing TPM Program, Phases 2-4

00:04:00

8How to Use TPM Activity Boards

00:06:35

9How to Develop a TPM Master Plan

00:06:45

10How to Use an Equipment Selection Table

00:04:51

You must be logged in to access Gemba Academy resources.