Frequently Asked Questions

Gemba Insights

Welcome to Gemba Insights, your comprehensive guide to frequently asked questions on your path to continuous improvement. Offering a variety of short videos, articles, and additional resources, Gemba Insights is dedicated to addressing your queries and illuminating new concepts. Whether you’re a subscriber or exploring what Gemba Academy offers, these resources are here to enhance your learning experience.

Featured Insight

Where Should We Start?

To start your lean journey effectively, it's crucial to understand your motivation, secure early wins with real financial impact, and establish a clear vision through learning from advanced lean organizations.

The Seven (or Eight) Deadly Wastes

Making Continuous Learning Fun

How to Reduce Employee Turnover

How to Promote Continuous Learning

How to Reduce Inventory

Five Lean Transformation Tips

Create a Lean Learning Path

How to Get Executive Buy-in for Lean Initiatives

How Much Does a Lean Journey Cost?

How to Use the 90-day Lean Roadmap

Where Should We Start?

What is Lean?

How to Deploy Training

What is a Project Charter?

What is Six Sigma?

What is Kaizen?

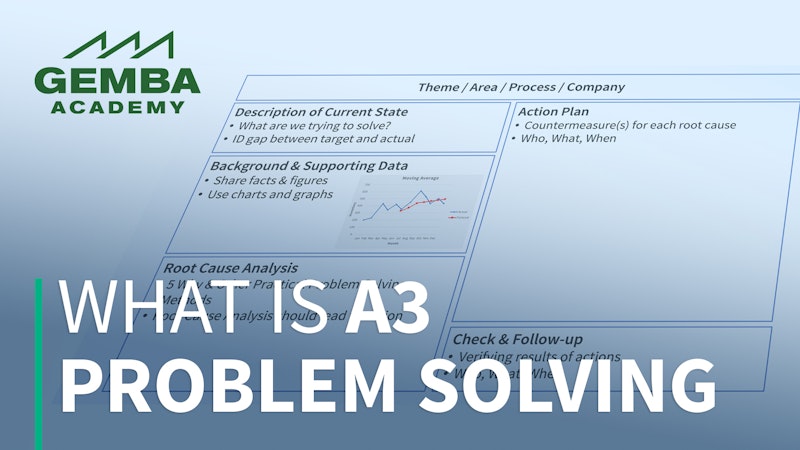

What is A3 Problem Solving?

What is FMEA?

What is Root Cause Analysis?

What are the 7 Basic Quality Tools?

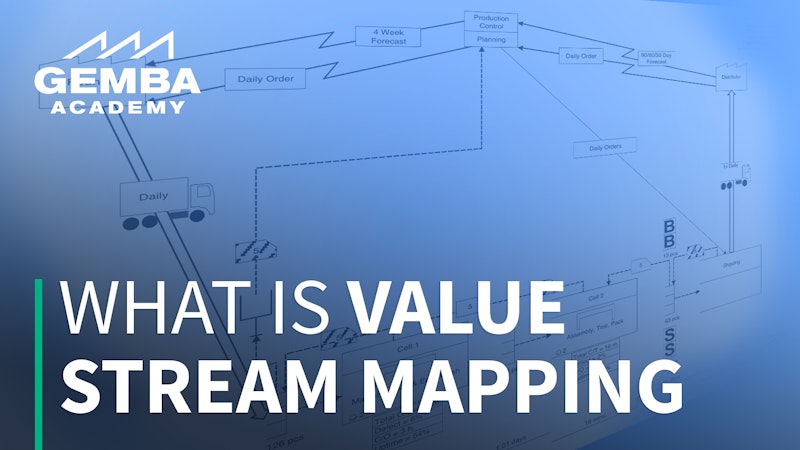

What is Value Stream Mapping?

What is 5S?

What is a Control Impact Matrix?

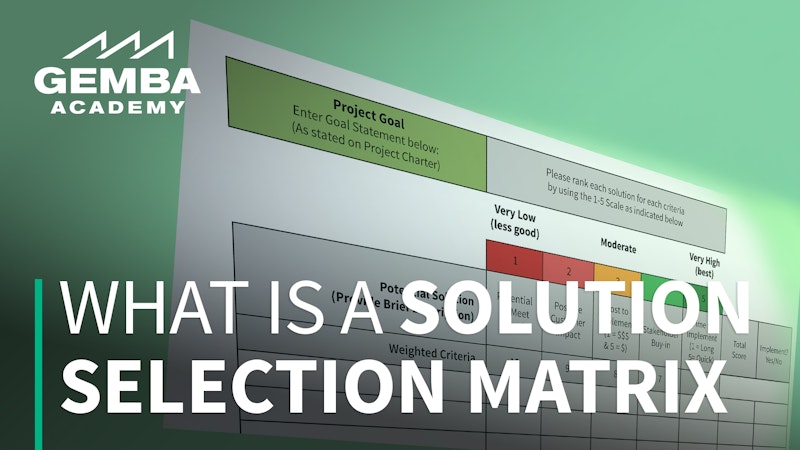

What is a Solution Selection Matrix?

What is Visual Management?

What is SIPOC?

What is Process Mapping?

What is Mistake-Proofing?

What is DPMO: Defects Per Million Opportunities?

What is SMED?

What is a Functional Deployment Map?

What is Cp / Cpk?

What About the 8th Waste?

Lean Journey Map: A Visual Guide to Bridging the Gap Between Current State and Future State

Don't Let Perfection Get in the Way of Progress

Rules in Use

What is Lean Accounting?

What is Lean Finance?

Eight Lessons for Sustaining Excellence

How Continuous Improvement Helps the P&L

Kamishibai Boards: A Visual Tool for Standard Work