90-Day Lean Roadmap

By Steven Kane • June 28, 2018

The 90-Day Get Started Plan is a model for guiding Gemba Academy subscribers through the first phases of a lean deployment. There is no single right way to begin a lean journey. This plan uses only a few lean practices and tools to get an organization started with both a lean management system and a lean production system in a pilot area.

- The intent is for your team to learn from the deployment in the pilot area in about 90 days. The lessons learned should then be used to deploy to the next area and the next.

- The roadmap is for people at various levels of the organization. It illustrates what is to be done and by whom while establishing a timeline for completion.

- The emphasis is on developing lean leadership routines along with continuous improvement and problem-solving routines.

Key Milestones

- Change Management: Upcoming changes are communicated to the organization. People are aware that work will be done differently, using lean methods and principles, and that they will be supported through this change. The essentials (who, what, when, where, why, and how) are clarified.

- Continuous Improvement Learning Begins: Supervisors teach associates in a pilot area 5S and coach them through the implementation and sustainment of 5S.

- Daily Gemba Walks Begin: Senior leaders walk through the value creating processes to see with their own eyes how customer needs are being met and how problems are being solved. They use their observations to coach the supervisors.

- Lean Management System Supports a Lean Production System: The beginnings of the lean management system are established and actively used at the various levels of leadership to support the lean production system. Key elements include:

- Visual Management: Whiteboards or other simple visual tools to make the work visible and to drive collaboration.

- Leader Standard Work: Simple leadership routines to support teams.

- Daily Accountability: Brief stand-up meetings, or huddles, to keep teams aligned with customer need, organizational goals, and problem solving.

- Associates Drive Continuous Improvement: The people who own the processes solve their own problems with coaching from supervisors.

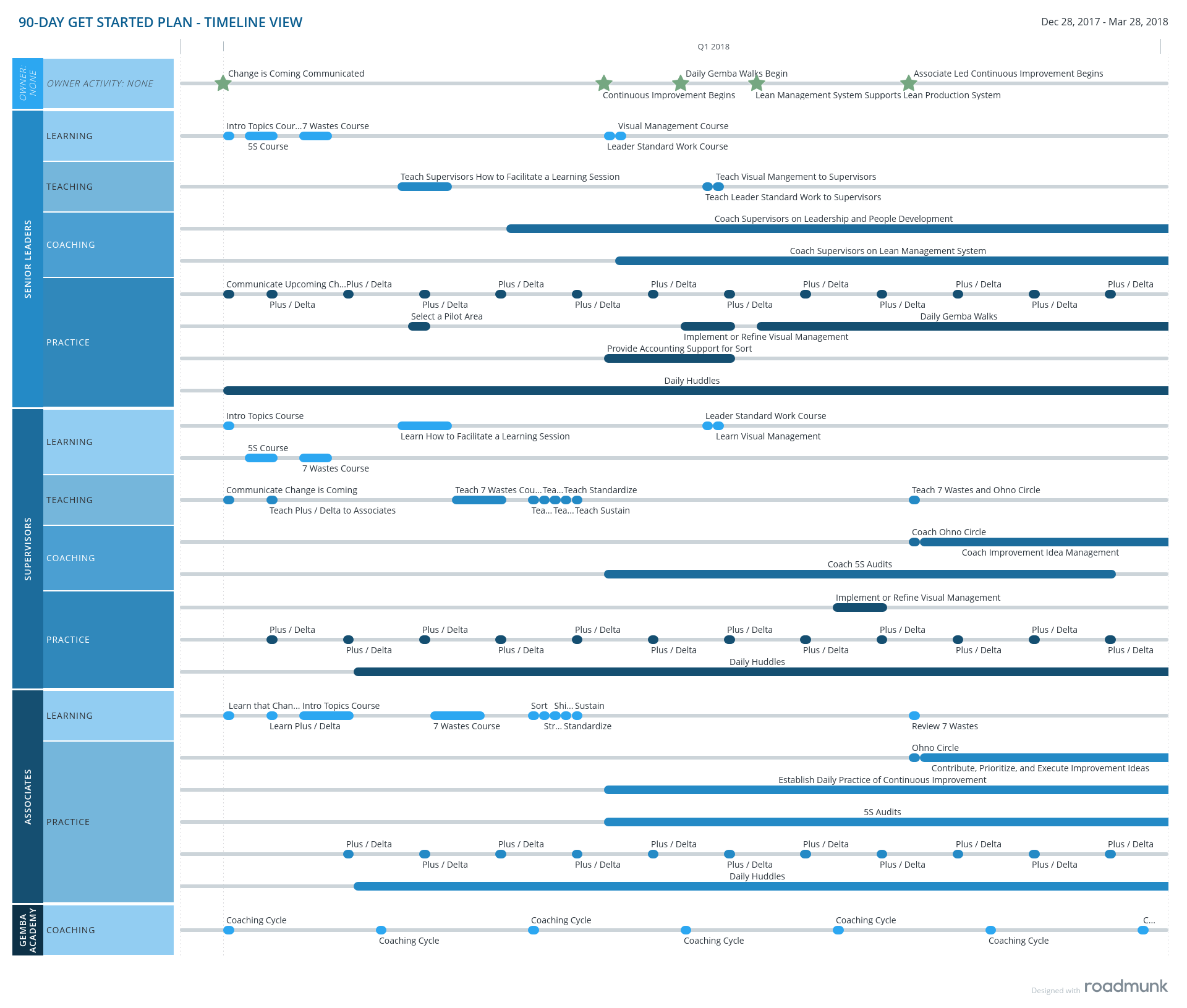

The roadmap consists of a timeline, a swim lane diagram, and a lean learning path. Any or all elements of the roadmap should be changed to suit the needs of your organization.

The Timeline

The timeline shows responsibilities for three roles: senior leaders, supervisors, and associates. The titles and layers of leadership will vary from one organization to the next. You’ll need to decide how to categorize the roles in your organization.

A key aspect of the timeline is the list of general responsibilities associated with each role. Leadership roles (both senior leaders and supervisors) are associated with learning, teaching, coaching, and practicing lean. What is to be learned, taught, coached, and practiced is listed on the timeline.

The sequence of events on the timeline is more important than the schedule. The recommendation is to move quickly, allowing no unnecessary delays.

Don’t let perfect get in the way of progress.

Mistakes will be made, and they will become great learning opportunities. Do your best to avoid analysis paralysis. You’re strongly encouraged to keep the team moving.

Simple, Visual, Manual

The suggestion is to write your own timeline on a whiteboard. While the example in this plan was created using information technology for simple distribution, a simple and manual visual timeline is essential to promote teamwork and clear communication.

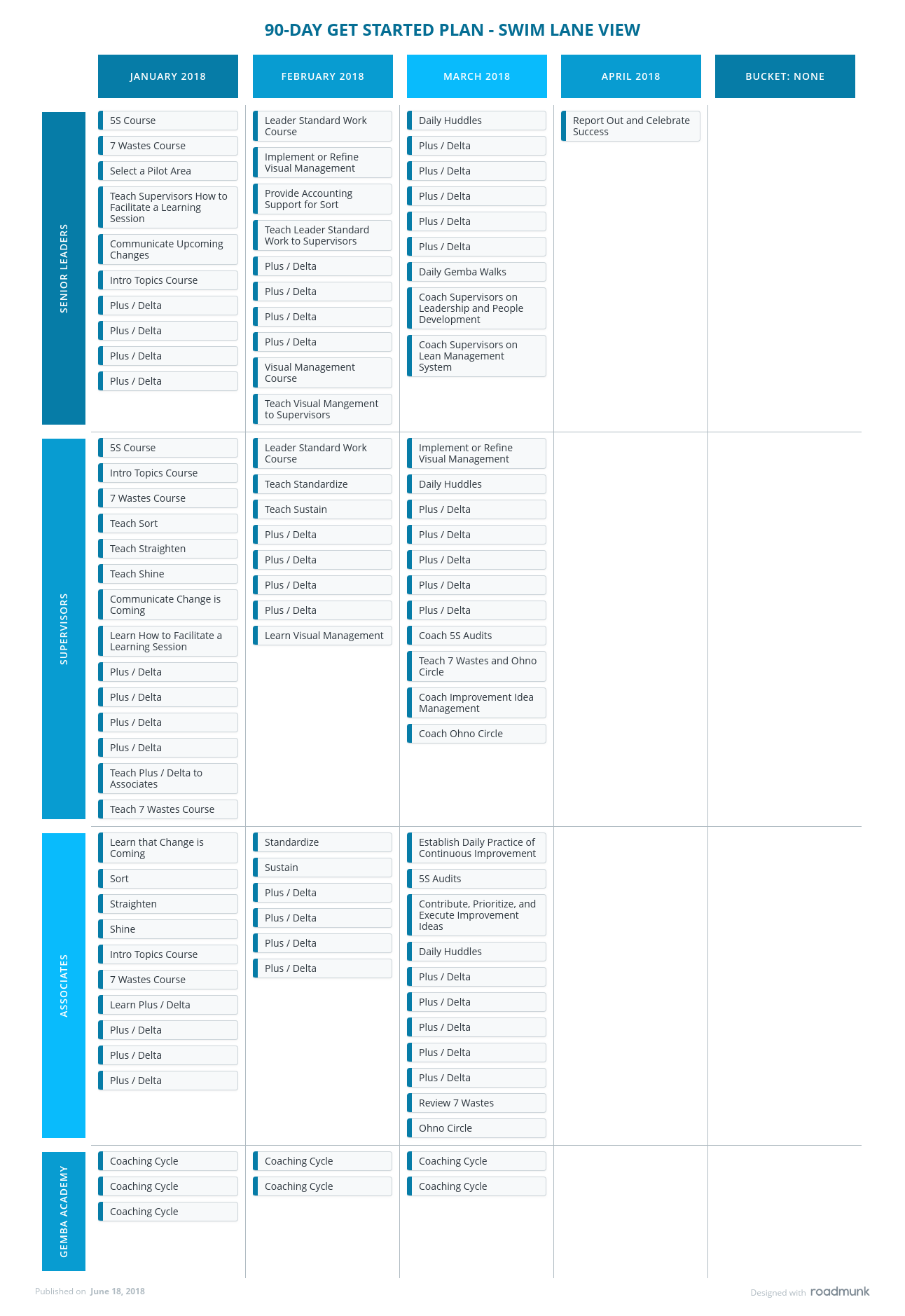

The Swim Lane Diagram

The swim lane diagram lists general tasks by role and time period. The example provided lists the tasks by month. You’re encouraged to do what works best for your team. The intent is to make the work visible and have the diagram illustrate workload and progress.

Again, a simple and manual system such as a whiteboard is suggested.

The Lean Learning Path

The lean learning path organizes Gemba Academy’s lean learning content in progression. It explains the general topic covered, its purpose, the related resources, and what to do at the place the work is done.

There are three parallel paths. One each for senior leaders, supervisors, and associates.

Roles and Responsibilities

The associate’s responsibility is to both create value for the customer and to continuously improve processes. The leader’s responsibility is to teach, coach, mentor, and inspire.

The timeline shows leaders learning a topic using Gemba Academy resources, then teaching direct reports. The conversations that come up and the questions addressed during learning sessions are a valuable part of the learning process. Not only does the learner develop an awareness of the topic presented, but also gains clarity on the direction of the organization and the intent of leadership.

Let Gemba Academy be the Subject Matter Expert

Leaders teaching lean topics can rely on Gemba Academy content to present the material. Facilitator guides and learner workbooks are included with the course content. Every learner gets the same message from one learning session to the next. Learning content can be reviewed quickly and easily in the training room or at the place the work is done.

Getting Support

Optional coaching support is available from the Gemba Academy Customer Success Team. Biweekly coaching calls are encouraged through this 90-day period. Our coaches are experienced lean leaders and practitioners.

To inquire about our coaching support, please contact us here. We’re here to help you be successful.