Fast Track to Green Belt Certification

Accelerate Your Lean Six Sigma Green Belt Certification Journey

Dallas-Fort Worth, TX

$3,695 per person

Fast-track your Lean Six Sigma certification! Strengthen your career opportunities, build your expertise in process improvement, and contribute to cost-saving initiatives. Enroll now to begin the prerequisite Yellow Belt portion of the program, before the Green Belt class begins. Limited spots available, register today!

Gemba Academy’s Green Belt Certification was created to help Lean and Six Sigma practitioners take their knowledge to the next level. It represents the first step toward becoming a Lean Leader, allowing learners to become process improvement specialists armed with the right tools and tactics for driving measurable improvements within an organization.

About

Earning a Lean Six Sigma Green Belt is a great first step toward becoming an advanced Lean and Six Sigma practitioner. This certification is designed to demonstrate a deep knowledge of continuous improvement methodologies and how to implement best practices in the workplace. Certified Green Belts are experts in identifying and analyzing problems and developing solutions that drive cost savings, quality improvements, and streamlined workflows.

Overview

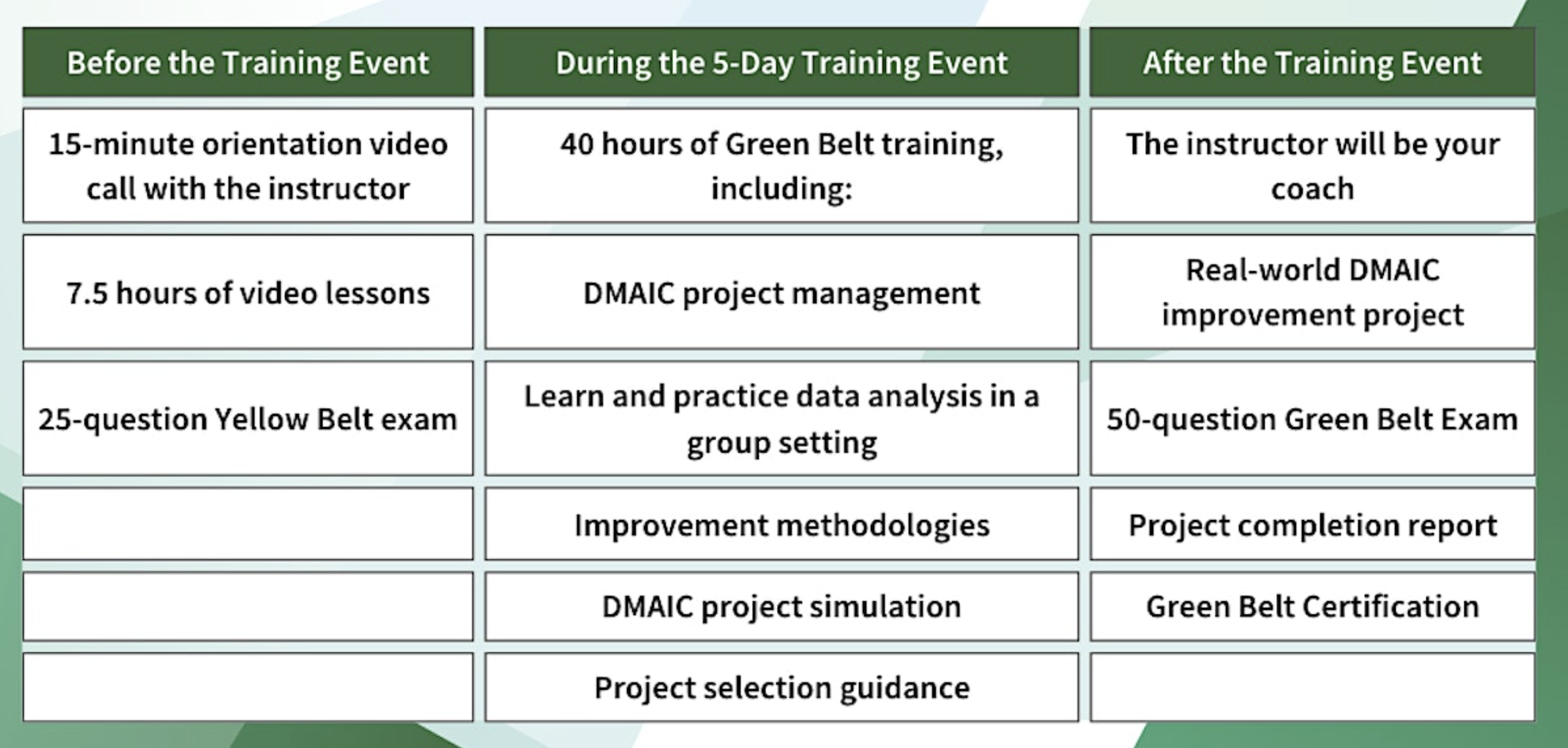

Fast Track Learning

Learners will complete our Yellow Belt curriculum before attending the 5-day session.

This will include 7.5 hours of video lessons, 1-hour exam (25 questions), and 15-minute orientation video call with a Gemba Academy coach

Hands-on Training

- After completing the virtual pre-work, candidates will join us in person for hands-on experiential learning.

- 5 Days, Mon- Fri: 8:30 am - 5 pm

- Green Belt Project and Online Exam will be completed outside of class time. The exam is a 2-hour open book exam within the Gemba Academy Learning System.

- Each candidate will participate in 15-minute virtual coaching calls after the in-person training for guidance as they work through their project.

What event types are available?

In-Person

At our Dallas-Fort Worth training center

Our modern, well-equipped training center gets your team all in one place, ready to tackle your improvement challenges.Virtual

From anywhere you have internet access

Unlike other webinars, our virtual training is designed to be engaging and impactful, regardless of where you are joining from in the world.On-Site

We come to your location

For your ultimate convenience, we can send a trainer directly to your facility to deliver training in your familiar surroundings.

Explore our other events.

Dallas-Fort Worth, TX

2-Day Lean Simulation Bootcamp

$1,850 per person

Seats are limited! Bring your team and delve into the key methods of lean.

Participants work as a team in a production simulation to understand the impact of process improvements by applying fundamental lean methods such as Toyota Kata, 5S, 7 Wastes, Flow, and Pull.

Participants reflect on gains by tracking their improvements through process metrics and P&L statements.

Learn More & Register

Dallas-Fort Worth, TX

Value Stream Mapping: From Chaos to Clarity

From $1250

Join us in person for a one-day, hands-on Value Stream Mapping (VSM) workshop at Gemba Academy’s training facility in Keller, TX.

Is your team aiming for better clarity, stronger collaboration, and smoother processes? Value Stream Mapping is a practical tool that helps you align around what matters most. Whether you're in manufacturing, healthcare, logistics, or a service environment, this workshop will show you how work really flows, and where it gets held up.

Learn More & Register

Online

Change Management: Interactive Webinar

$75 - $99

Navigate Change with Confidence

Learn tools to lead change confidently, reduce resistance, and communicate clearly for smoother organizational transitions.