Unlock Over 2,000 Lessons

Subscribe today and join the thousands of worldclass organizations already learning with Gemba Academy.

Focused Improvement of Idling and Minor Stops

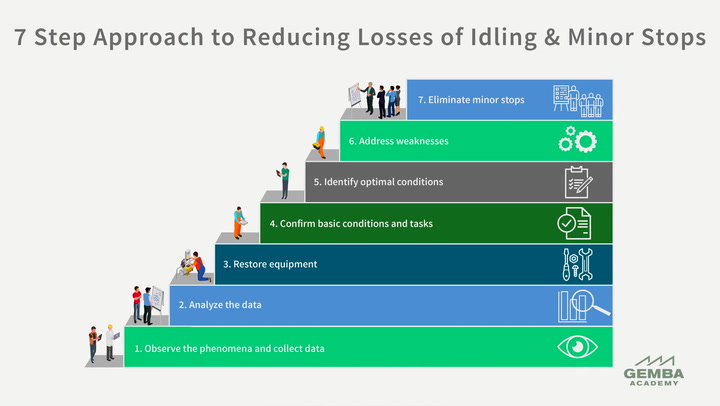

Idling and minor stops are often less visible but surprisingly large contributors to equipment losses. Because minor stops are quick and easy to correct without repair or replacing parts, they are fundamentally different from failures and machine breakdowns. Learn the seven-step approach to addressing minor stop losses, the three metrics for tracking progress toward zero minor stops, and the importance of classifying and investigating the phenomena related to chronic losses.

Course Videos

What Is Focused Improvement?

06:54

2The Six Big Losses

07:27

3Getting Started with Focused Improvement

07:56

4Focused Improvement of Changeover Losses

02:02

5Focused Improvement of Startup and Yield Losses

03:11

Current Video

Focused Improvement of Idling and Minor Stops

04:50

Next VideoFocused Improvement of Speed Losses

04:21

8Focused Improvement of Breakdown Losses

04:46

9Focused Improvement of Defect Losses

04:04

10Practical Problem Solving for Focused Improvement

07:46

11How To Do a Loss Analysis

05:17

12What Is a TPM Small Group Activity?

05:40

13How to Create a Failure Map

04:27

You must be logged in to access Gemba Academy resources.